- Home Page

- Company Profile

-

Our Products

- Induction Melting Machine

- Gold Melting Machine

- Induction Based Gold Melting Machine 500 Gms. In Single Phase

- Induction Based Gold Melting Machine

- Gold Melting Machine 3PH

- Induction Based Gold Melting Machine 20 kg. With Tilting Unit

- Induction Based Gold Melting Machine 10 Kg. With Tilting Unit

- Silver Melting Machine

- Induction Based Melting Machine 10 kg. With Tilting Unit

- Gold Melting Machine 12Kg With Tilting Unit

- Induction Based Gold Melting Machine 3 Kg. In Three Phase

- Induction Melting Machine With Tilting Unit

- Induction Based Gold Melting Machine 30 Kg. With Tilting Unit

- Induction Based Gold Melting Machine 2 Kg. In Three Phase

- Induction Gold Melting Machine

- Induction Based Melting Machine 500 Gms. In Sigle Phase

- Jewelry Melting Furnace

- Gold Melting Furnace

- Induction Melting Furnace

- Induction Based Gold Melting Furnace 2 Kg. In 3PH

- Induction Based Gold Melting Furnace 3 Kg. In 3PH

- Induction Based Gold Melting Furnace 5 Kg. In Three Phase

- Induction Based Gold Melting Furnace 12 Kg. With Tilting Unit

- Gold Melting Furnace

- induction Melting Machine

- Mini Plus Gold Melting Machine 1 Kg. In Single Phase

- Induction Based Gold Melting Furnace 4 Kg in Three Phase

- Induction Based Gold Melting Furnace

- Induction Based Gold Melting Machine In Single Phase

- Induction Based Gold Melting Furnace 500 Gms. In Single Phase

- Induction Based Gold Melting Furnace 8 kg. With Tilting Unit

- Induction Based Gold Melting Furnace 15 kG. With Tilting Unit

- Induction Based Gold Melting Furnace 20 Kg. With Tilting Unit

- Induction Based Gold Melting Furnace 25 Kg. With Tilting Unit

- Induction Based Gold Melting Furnace 30 Kg. With Tilting Unit

- Gold Casting Machine

- Bottom Pouring Vacuum Casting Machine

- Induction Based Gold Casting Machine 2 kg. In Three Phase

- Induction Based Casting Machine

- Induction Based Gold Casting Furnace 3 Kg In Single Phase

- Gold Casting Machine

- 3 in 1 Gold Casting Machine

- Induction Based Gold Casting Machine 1 kg. In Single Phase

- Jewellery Casting Machine

- Gold Bar Making Machine

- 1 Kg Bar Vacuum Casting Making Machine

- Bar Making Machine 100grm 4 Bar At A Time

- Induction Based Gold Casting Machine 3 kg. Three Phase

- Induction Based Jewellery Casting Machine

- jewelry vacuum casting unit

- 1kg Gold Casting Machine

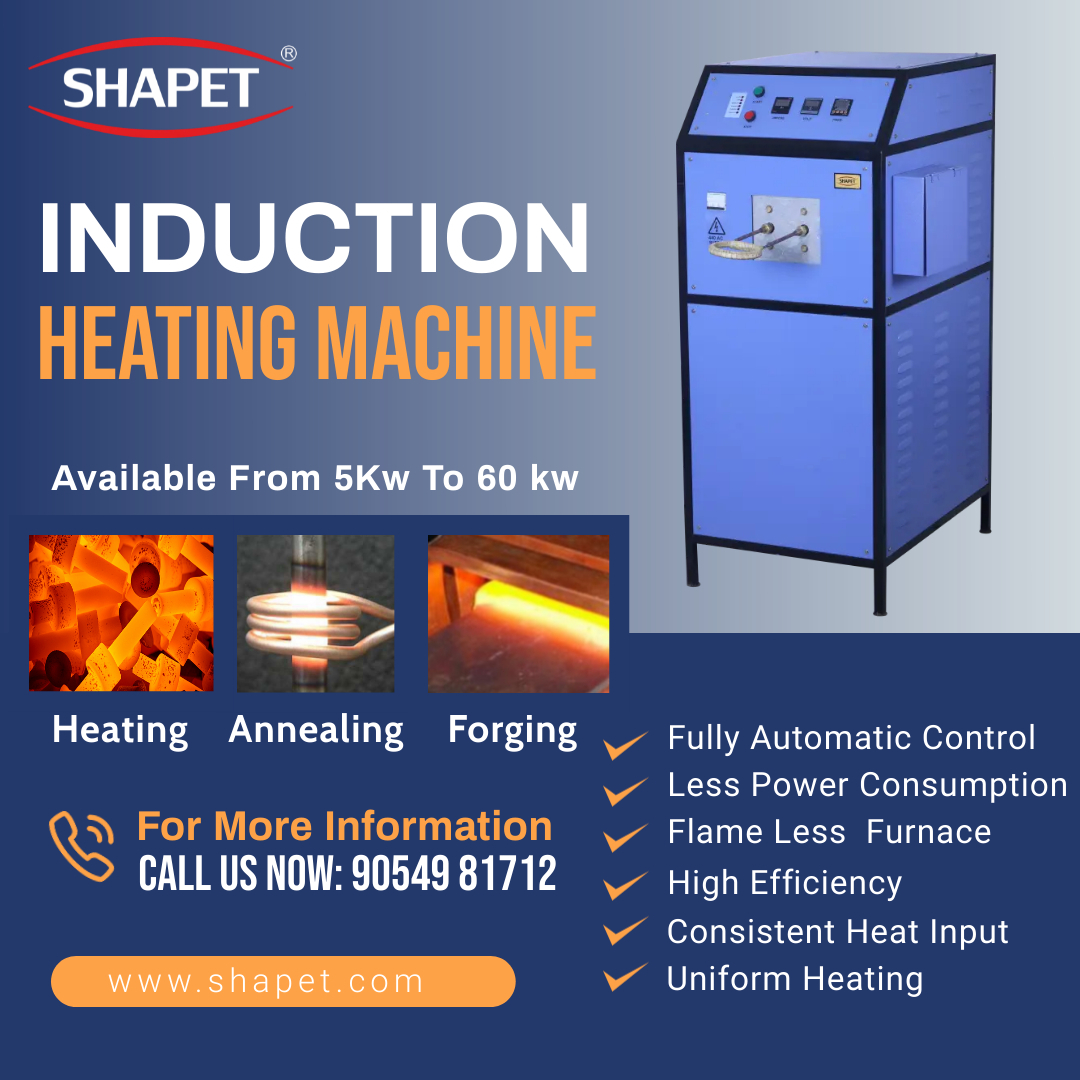

- Heating Machine

- Silver Melting Machine

- Gold And Silver Granulating Machine With Inbuilt Chiller

- Induction melting machine 3PH

- Induction Based Silver Melting Furnace

- Silver Melting Furnace With Tilting

- Induction melting machine

- Induction Based Silver Melting Machine 250 Gms. In Single Phase

- Induction Based Silver Melting Machine 1.5 Kg. In Three Phase

- Induction Based Silver Melting Machine 2 Kg.In Three Phase

- Induction Based Silver Melting Machine 2.5 Kg. In Three Phase

- Induction Based Silver Melting Machine 4 kg. With Tilting Unit

- Induction Based Silver Melting Machine 5 Kg. With Tilting Unit

- Induction Based Silver Melting Machine 7.5 Kg. With Tilting Unit

- Induction Based Silver Melting Machine 10 kG. With Tilting Unit

- Induction Based Silver Melting Machine 15 Kg. With Tilting Unit

- Silver Melting Furnace

- Induction Based Melting Furnace 5 kg. With Titing Unit

- Silver Melting Furnace

- Induction Based Silver Melting Machine 05 KG WITH MELTING POT

- Induction Based Silver Melting Furnace 1 kg. In Three Phase

- Induction Based Silver Melting Furnace 1.5 Kg. In Three Phase

- Induction Based Silver Melting Furnace 2 kg. In Three Phase

- Induction Based Silver Melting Furnace 2.5 Kg. In Three Phase

- Induction Based Silver Melting Furnace 5 kg. With Tilting Unit

- Induction Based Silver Melting Furnace 6 Kg. With Tilting Unit

- Induction Based Silver Melting Furnace 7.5 Kg. With Tilting Unit

- Induction Based Silver Melting Furnace 10 kg. With Tilting Unit

- Induction Based Silver Melting Furnace 15 kg. With Tilting Unit

- Induction Based Silver Melting furnace 12.5 Kg. With Tilting Unit

- Silver Casting Furnace

- Silver Casting Machine

- Copper Melting Furnace

- Induction Based Copper Melting Furnace with Tilting Unit

- Induction Based Copper Melting Furnace

- 3PH Induction Based Copper Melting Furnace

- 10 Kg. Induction Based Silver Melting Furnace

- Induction Copper Melting Furnace

- Copper Melting Furnace

- Copper Melting Furnace with Hydraulic Tilting Unit

- Copper Melting Furnace

- Single Phase Induction Based Copper Melting Furnace

- Induction Based Melting Furnace 10 kg. With Tilting Unit

- Three Phase Copper Melting Furnace

- Induction Copper Melting Furnace

- Copper Melting Machine

- Melting Machine For Gold / Silver

- Copper Melting Machine with Tilting Unit

- Induction Based Copper Melting Machine

- Copper Melting Machine

- Induction Based Copper Melting Machine 1.5 kg. In Three Phase

- Induction Based Copper Melting Machine 2 kg. In Three Phase

- Induction Based Copper Melting Machine 2.5 kg. In Three Phase

- Induction Based Copper Melting Machine 4 Kg. With Tilting Unit

- induction Based Copper Melting Machine 5 kg. With Tilting Unit

- Induction Based Copper Melting Machine 15 Kg. With Tilting Unit

- Gold Melting Machine

- Carbon & Graphite Products

- Imitation Casting

- Induction Brazing Machine

- Gold Casting Furnace

- jewellery casting

- Induction Melting Machine

- Gallery

- Contact Us

Induction Hardening Machine

310000 INR/Unit

Product Details:

- Usage Metal Hardening Machine

- Type Induction Based Hardening

- Application Metal hardning , Annaling or Heating

- Product Type Induction Based Hardening

- Color Gray

- Click to View more

X

Induction Hardening Machine Price And Quantity

- 310000 INR/Unit

- 1 Unit

Induction Hardening Machine Product Specifications

- Induction Based Hardening

- Metal hardning , Annaling or Heating

- Induction Based Hardening

- Metal Hardening Machine

- Gray

Induction Hardening Machine Trade Information

- Kandla Port

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 10 Unit Per Day

- 1 Week

- Contact us for information regarding our sample policy

- All India

Product Description

Shapet Induction Hardening Machine is a type of induction furnace that produces heat on the principle of electromagnetic induction. A metal job is placed to be heated inside Induction Coil and quenched to dive, a needed transformation that makes metal hardened and brittle.We are manufacturers of Induction Hardening machines with high efficiency, durability, and reliability utilizing quality materials. We are manufacturing and supplying a broad array of Induction Hardening Machines, which are used for surface and through-hardening. Along with the offered induction hardening machine, we give solutions to auto parts, and hand tools industries also We are manufacturing customized machines according to application.

Typical applications of induction hardening include Gears, Shafts, Axles, Cam lobes, Stampings, and Spindles, mostly Symmetrical parts. Induction hardening is used to strengthen a specific area of a part. Single-piece, surface hardening of selective areas.

Advanced Induction Technology

This machine harnesses the power of induction heating, enabling precise control over temperature and treatment cycles. The process is fast, energy-efficient, and ensures consistent quality across diverse metal parts, making it indispensable in modern manufacturing environments.

Reliable Performance & Support

With a 1-year warranty and robust construction, users benefit from uninterrupted operation and reduced maintenance. As a trusted exporter, manufacturer, and supplier in India, comprehensive customer support and technical assistance ensure smooth integration in industrial workflows.

FAQs of Induction Hardening Machine:

Q: How does the induction hardening machine improve the hardness of metal components?

A: The machine uses electromagnetic induction to generate localized heat, quickly elevating the temperature of metal surfaces. Controlled quenching follows, transforming the metals structure for increased hardness and wear resistance, making components suitable for heavy-duty applications.Q: What types of metals can be processed using this induction hardening machine?

A: It is suitable for treating various ferrous and non-ferrous metals, including steel and alloys. The versatile technology makes it effective for metal hardening, annealing, and heat treatment tasks across multiple industrial domains.Q: When is induction hardening recommended over traditional hardening methods?

A: Induction hardening is preferred when rapid, controlled heating is required, minimizing distortion and ensuring repeatability. It is ideal for parts that demand high surface hardness without compromising the cores ductility, such as shafts and gears.Q: Where can this metal hardening machine be installed for optimal performance?

A: The machine is designed for integration into factory floors, manufacturing units, and metalworking facilities. Compact yet powerful, it fits well in both standalone and production line setups, ensuring seamless workflow.Q: What is the process involved in induction-based metal hardening?

A: The process starts with targeted induction heating of the metal surface, followed by swift cooling (quenching). This sequence refines the surface microstructure, significantly increasing hardness while retaining internal strength.Q: How does the warranty benefit buyers of the induction hardening machine?

A: A 1-year warranty offers buyers peace of mind, backing the machines quality and performance. It enables prompt resolution of manufacturing defects or operational issues, reducing downtime during initial use.Q: What are the key benefits of using an induction hardening machine for industrial metal treatment?

A: Induction hardening delivers energy efficiency, precise control, consistent quality, and reduced processing times. Its advanced technology minimizes scrap, ensures superior surface properties, and contributes to overall cost-effectiveness in metalworking operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email