- Home Page

- Company Profile

-

Our Products

- Induction Melting Machine

- Gold Melting Machine

- Induction Based Gold Melting Machine 500 Gms. In Single Phase

- Induction Based Gold Melting Machine

- Gold Melting Machine 3PH

- Induction Based Gold Melting Machine 20 kg. With Tilting Unit

- Induction Based Gold Melting Machine 10 Kg. With Tilting Unit

- Silver Melting Machine

- Induction Based Melting Machine 10 kg. With Tilting Unit

- Gold Melting Machine 12Kg With Tilting Unit

- Induction Based Gold Melting Machine 3 Kg. In Three Phase

- Induction Melting Machine With Tilting Unit

- Induction Based Gold Melting Machine 30 Kg. With Tilting Unit

- Induction Based Gold Melting Machine 2 Kg. In Three Phase

- Induction Gold Melting Machine

- Induction Based Melting Machine 500 Gms. In Sigle Phase

- Jewelry Melting Furnace

- Gold Melting Furnace

- Induction Melting Furnace

- Induction Based Gold Melting Furnace 2 Kg. In 3PH

- Induction Based Gold Melting Furnace 3 Kg. In 3PH

- Induction Based Gold Melting Furnace 5 Kg. In Three Phase

- Induction Based Gold Melting Furnace 12 Kg. With Tilting Unit

- Gold Melting Furnace

- induction Melting Machine

- Mini Plus Gold Melting Machine 1 Kg. In Single Phase

- Induction Based Gold Melting Furnace 4 Kg in Three Phase

- Induction Based Gold Melting Furnace

- Induction Based Gold Melting Machine In Single Phase

- Induction Based Gold Melting Furnace 500 Gms. In Single Phase

- Induction Based Gold Melting Furnace 8 kg. With Tilting Unit

- Induction Based Gold Melting Furnace 15 kG. With Tilting Unit

- Induction Based Gold Melting Furnace 20 Kg. With Tilting Unit

- Induction Based Gold Melting Furnace 25 Kg. With Tilting Unit

- Induction Based Gold Melting Furnace 30 Kg. With Tilting Unit

- Gold Casting Machine

- Bottom Pouring Vacuum Casting Machine

- Induction Based Gold Casting Machine 2 kg. In Three Phase

- Induction Based Casting Machine

- Induction Based Gold Casting Furnace 3 Kg In Single Phase

- Gold Casting Machine

- 3 in 1 Gold Casting Machine

- Induction Based Gold Casting Machine 1 kg. In Single Phase

- Jewellery Casting Machine

- Gold Bar Making Machine

- 1 Kg Bar Vacuum Casting Making Machine

- Bar Making Machine 100grm 4 Bar At A Time

- Induction Based Gold Casting Machine 3 kg. Three Phase

- Induction Based Jewellery Casting Machine

- jewelry vacuum casting unit

- 1kg Gold Casting Machine

- Heating Machine

- Silver Melting Machine

- Gold And Silver Granulating Machine With Inbuilt Chiller

- Induction melting machine 3PH

- Induction Based Silver Melting Furnace

- Silver Melting Furnace With Tilting

- Induction melting machine

- Induction Based Silver Melting Machine 250 Gms. In Single Phase

- Induction Based Silver Melting Machine 1.5 Kg. In Three Phase

- Induction Based Silver Melting Machine 2 Kg.In Three Phase

- Induction Based Silver Melting Machine 2.5 Kg. In Three Phase

- Induction Based Silver Melting Machine 4 kg. With Tilting Unit

- Induction Based Silver Melting Machine 5 Kg. With Tilting Unit

- Induction Based Silver Melting Machine 7.5 Kg. With Tilting Unit

- Induction Based Silver Melting Machine 10 kG. With Tilting Unit

- Induction Based Silver Melting Machine 15 Kg. With Tilting Unit

- Silver Melting Furnace

- Induction Based Melting Furnace 5 kg. With Titing Unit

- Silver Melting Furnace

- Induction Based Silver Melting Machine 05 KG WITH MELTING POT

- Induction Based Silver Melting Furnace 1 kg. In Three Phase

- Induction Based Silver Melting Furnace 1.5 Kg. In Three Phase

- Induction Based Silver Melting Furnace 2 kg. In Three Phase

- Induction Based Silver Melting Furnace 2.5 Kg. In Three Phase

- Induction Based Silver Melting Furnace 5 kg. With Tilting Unit

- Induction Based Silver Melting Furnace 6 Kg. With Tilting Unit

- Induction Based Silver Melting Furnace 7.5 Kg. With Tilting Unit

- Induction Based Silver Melting Furnace 10 kg. With Tilting Unit

- Induction Based Silver Melting Furnace 15 kg. With Tilting Unit

- Induction Based Silver Melting furnace 12.5 Kg. With Tilting Unit

- Silver Casting Furnace

- Silver Casting Machine

- Copper Melting Furnace

- Induction Based Copper Melting Furnace with Tilting Unit

- Induction Based Copper Melting Furnace

- 3PH Induction Based Copper Melting Furnace

- 10 Kg. Induction Based Silver Melting Furnace

- Induction Copper Melting Furnace

- Copper Melting Furnace

- Copper Melting Furnace with Hydraulic Tilting Unit

- Copper Melting Furnace

- Single Phase Induction Based Copper Melting Furnace

- Induction Based Melting Furnace 10 kg. With Tilting Unit

- Three Phase Copper Melting Furnace

- Induction Copper Melting Furnace

- Copper Melting Machine

- Melting Machine For Gold / Silver

- Copper Melting Machine with Tilting Unit

- Induction Based Copper Melting Machine

- Copper Melting Machine

- Induction Based Copper Melting Machine 1.5 kg. In Three Phase

- Induction Based Copper Melting Machine 2 kg. In Three Phase

- Induction Based Copper Melting Machine 2.5 kg. In Three Phase

- Induction Based Copper Melting Machine 4 Kg. With Tilting Unit

- induction Based Copper Melting Machine 5 kg. With Tilting Unit

- Induction Based Copper Melting Machine 15 Kg. With Tilting Unit

- Gold Melting Machine

- Carbon & Graphite Products

- Imitation Casting

- Induction Brazing Machine

- Gold Casting Furnace

- jewellery casting

- Imitation Casting Machine

- Induction Melting Machine

- Gallery

- Contact Us

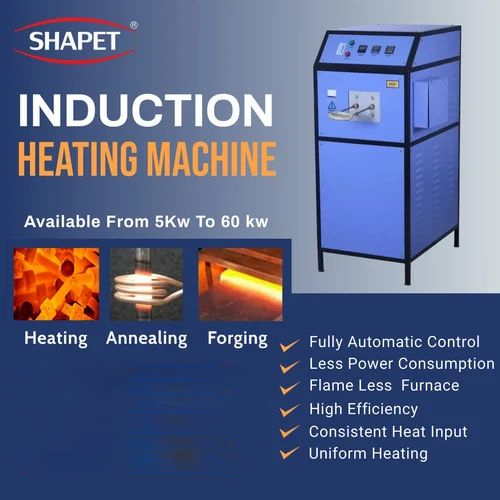

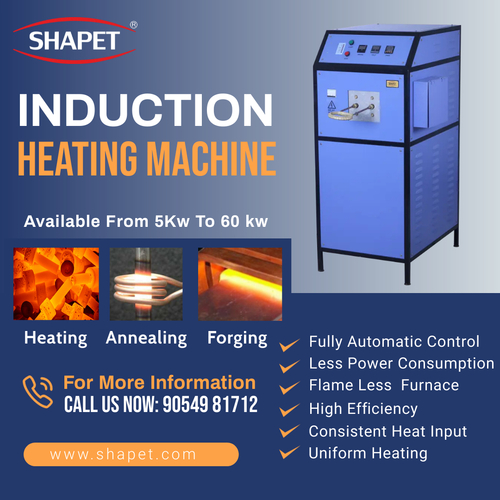

Induction Annealing Furnaces

150000 INR/Unit

Product Details:

- Usage Industrial

- Type Induction Based Heating

- Size 800.00 x 597.00 x 1130.00

- Application Metal Brazing, Annaling or Heating

- Height 1130 Millimeter (mm)

- Product Type Induction Based Melting

- Max. Input Power 440 Volt (V)

- Click to View more

X

Induction Annealing Furnaces Price And Quantity

- 150000 INR/Unit

- 1 Unit

Induction Annealing Furnaces Product Specifications

- Industrial

- Induction Based Melting

- Metal Brazing, Annaling or Heating

- 597 Millimeter (mm)

- 800 Millimeter (mm)

- Induction Based Heating

- 440 Volt (V)

- 800.00 x 597.00 x 1130.00

- Blue

- 1130 Millimeter (mm)

Induction Annealing Furnaces Trade Information

- Kandla Port

- 10 Unit Per Week

- 1 Week

- Contact us for information regarding our sample policy

- All India

Product Description

Induction heating provides improved control of the annealing process. Repeatable heating profiles can easily be obtained by precise regulation of the heating power. Since the workpiece is directly heated by the magnetic field, a faster response can be achieved. Moreover, the high overall efficiency of the induction heating process is crucial for such a lengthy treatment.Specification/Additional Details

Efficient Heating Performance

Leveraging induction-based heating, this furnace enables swift and uniform temperature control for metal brazing and annealing. Its powerful 440V operation supports continuous industrial usage, reducing cycle times while maintaining high precision and energy efficiency.

Rugged Construction for Industrial Use

Made from premium steel alloy, the furnace is built to withstand rigorous industrial environments. Its blue finish and compact form factor (800 x 597 x 1130 mm) make it easy to integrate into various manufacturing setups without stalling production efficiency.

Trusted Supply Network Across India

Manufactured, supplied, and exported by established companies in India, the induction annealing furnace is accessible nationwide. Expert support and reliable post-sale services, including a one-year warranty, ensure confidence in product performance and lifecycle.

FAQs of Induction Annealing Furnaces:

Q: How does the induction annealing furnace operate for metal brazing and heating?

A: The furnace utilizes electromagnetic induction to generate heat directly within steel alloy components. This method ensures rapid, uniform heating, which is ideal for brazing, annealing, or heating metals in industrial applications.Q: What is the warranty period and what does it cover?

A: The induction annealing furnace comes with a one-year warranty covering manufacturing defects and major functional issues. Detailed coverage and support information are provided upon purchase from authorized exporters, manufacturers, or suppliers.Q: Where can this furnace be used in the industrial sector?

A: The furnace is designed for versatile industrial usage, including manufacturing units, metal workshops, and other facilities requiring precise metal brazing, annealing, or heating operations.Q: What are the benefits of using induction-based heating over conventional methods?

A: Induction heating provides significant advantages such as energy efficiency, faster heating times, and enhanced control over temperature, resulting in improved product quality and reduced operational costs.Q: How should the furnace be maintained to ensure optimal performance?

A: Routine maintenance involves checking for wear on steel alloy components, ensuring electrical connections are secure, and cleaning the blue-coated surface to protect against corrosion. Periodic professional inspections are recommended for safety and efficiency.Q: What is the maximum input power and size of the furnace?

A: The furnace operates at a maximum input power of 440 volts and measures 800 mm in length, 597 mm in width, and 1130 mm in height, making it suitable for various industrial settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email