- Home Page

- Company Profile

-

Our Products

- Induction Melting Machine

- Gold Melting Machine

- Induction Based Gold Melting Machine 500 Gms. In Single Phase

- Induction Based Gold Melting Machine

- Gold Melting Machine 3PH

- Induction Based Gold Melting Machine 20 kg. With Tilting Unit

- Induction Based Gold Melting Machine 10 Kg. With Tilting Unit

- Silver Melting Machine

- Induction Based Melting Machine 10 kg. With Tilting Unit

- Gold Melting Machine 12Kg With Tilting Unit

- Induction Based Gold Melting Machine 3 Kg. In Three Phase

- Induction Melting Machine With Tilting Unit

- Induction Based Gold Melting Machine 30 Kg. With Tilting Unit

- Induction Based Gold Melting Machine 2 Kg. In Three Phase

- Induction Gold Melting Machine

- Induction Based Melting Machine 500 Gms. In Sigle Phase

- Jewelry Melting Furnace

- Gold Melting Furnace

- Induction Melting Furnace

- Induction Based Gold Melting Furnace 2 Kg. In 3PH

- Induction Based Gold Melting Furnace 3 Kg. In 3PH

- Induction Based Gold Melting Furnace 5 Kg. In Three Phase

- Induction Based Gold Melting Furnace 12 Kg. With Tilting Unit

- Gold Melting Furnace

- induction Melting Machine

- Mini Plus Gold Melting Machine 1 Kg. In Single Phase

- Induction Based Gold Melting Furnace 4 Kg in Three Phase

- Induction Based Gold Melting Furnace

- Induction Based Gold Melting Machine In Single Phase

- Induction Based Gold Melting Furnace 500 Gms. In Single Phase

- Induction Based Gold Melting Furnace 8 kg. With Tilting Unit

- Induction Based Gold Melting Furnace 15 kG. With Tilting Unit

- Induction Based Gold Melting Furnace 20 Kg. With Tilting Unit

- Induction Based Gold Melting Furnace 25 Kg. With Tilting Unit

- Induction Based Gold Melting Furnace 30 Kg. With Tilting Unit

- Gold Casting Machine

- Bottom Pouring Vacuum Casting Machine

- Induction Based Gold Casting Machine 2 kg. In Three Phase

- Induction Based Casting Machine

- Induction Based Gold Casting Furnace 3 Kg In Single Phase

- Gold Casting Machine

- 3 in 1 Gold Casting Machine

- Induction Based Gold Casting Machine 1 kg. In Single Phase

- Jewellery Casting Machine

- Gold Bar Making Machine

- 1 Kg Bar Vacuum Casting Making Machine

- Bar Making Machine 100grm 4 Bar At A Time

- Induction Based Gold Casting Machine 3 kg. Three Phase

- Induction Based Jewellery Casting Machine

- jewelry vacuum casting unit

- 1kg Gold Casting Machine

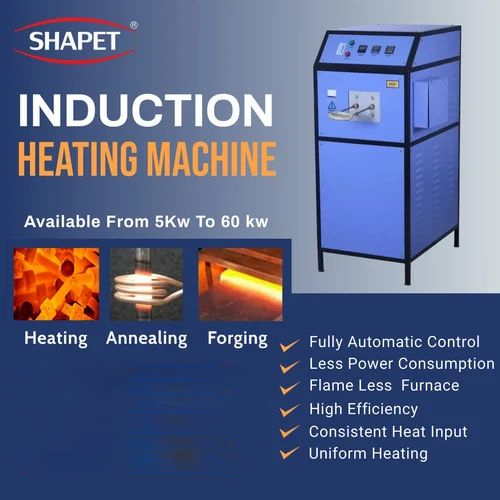

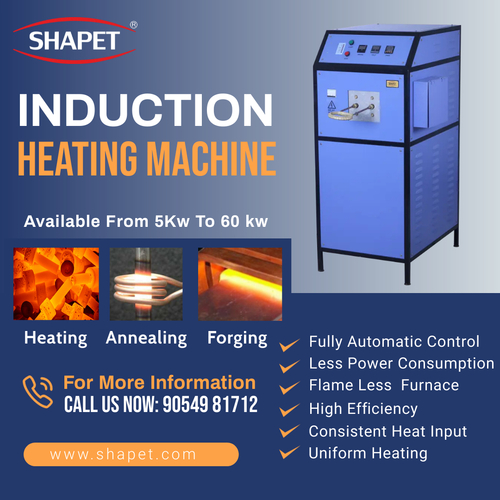

- Heating Machine

- Silver Melting Machine

- Gold And Silver Granulating Machine With Inbuilt Chiller

- Induction melting machine 3PH

- Induction Based Silver Melting Furnace

- Silver Melting Furnace With Tilting

- Induction melting machine

- Induction Based Silver Melting Machine 250 Gms. In Single Phase

- Induction Based Silver Melting Machine 1.5 Kg. In Three Phase

- Induction Based Silver Melting Machine 2 Kg.In Three Phase

- Induction Based Silver Melting Machine 2.5 Kg. In Three Phase

- Induction Based Silver Melting Machine 4 kg. With Tilting Unit

- Induction Based Silver Melting Machine 5 Kg. With Tilting Unit

- Induction Based Silver Melting Machine 7.5 Kg. With Tilting Unit

- Induction Based Silver Melting Machine 10 kG. With Tilting Unit

- Induction Based Silver Melting Machine 15 Kg. With Tilting Unit

- Silver Melting Furnace

- Induction Based Melting Furnace 5 kg. With Titing Unit

- Silver Melting Furnace

- Induction Based Silver Melting Machine 05 KG WITH MELTING POT

- Induction Based Silver Melting Furnace 1 kg. In Three Phase

- Induction Based Silver Melting Furnace 1.5 Kg. In Three Phase

- Induction Based Silver Melting Furnace 2 kg. In Three Phase

- Induction Based Silver Melting Furnace 2.5 Kg. In Three Phase

- Induction Based Silver Melting Furnace 5 kg. With Tilting Unit

- Induction Based Silver Melting Furnace 6 Kg. With Tilting Unit

- Induction Based Silver Melting Furnace 7.5 Kg. With Tilting Unit

- Induction Based Silver Melting Furnace 10 kg. With Tilting Unit

- Induction Based Silver Melting Furnace 15 kg. With Tilting Unit

- Induction Based Silver Melting furnace 12.5 Kg. With Tilting Unit

- Silver Casting Furnace

- Silver Casting Machine

- Copper Melting Furnace

- Induction Based Copper Melting Furnace with Tilting Unit

- Induction Based Copper Melting Furnace

- 3PH Induction Based Copper Melting Furnace

- 10 Kg. Induction Based Silver Melting Furnace

- Induction Copper Melting Furnace

- Copper Melting Furnace

- Copper Melting Furnace with Hydraulic Tilting Unit

- Copper Melting Furnace

- Single Phase Induction Based Copper Melting Furnace

- Induction Based Melting Furnace 10 kg. With Tilting Unit

- Three Phase Copper Melting Furnace

- Induction Copper Melting Furnace

- Copper Melting Machine

- Melting Machine For Gold / Silver

- Copper Melting Machine with Tilting Unit

- Induction Based Copper Melting Machine

- Copper Melting Machine

- Induction Based Copper Melting Machine 1.5 kg. In Three Phase

- Induction Based Copper Melting Machine 2 kg. In Three Phase

- Induction Based Copper Melting Machine 2.5 kg. In Three Phase

- Induction Based Copper Melting Machine 4 Kg. With Tilting Unit

- induction Based Copper Melting Machine 5 kg. With Tilting Unit

- Induction Based Copper Melting Machine 15 Kg. With Tilting Unit

- Gold Melting Machine

- Carbon & Graphite Products

- Imitation Casting

- Induction Brazing Machine

- Gold Casting Furnace

- jewellery casting

- Induction Melting Machine

- Gallery

- Contact Us

Rotor Brazing Machine

195000.0 INR/Unit

Product Details:

- Usage submersible rotor brazing

- Application Induction Brazing

- Height 56 Inch (in)

- Product Type Rotor Brazing Machine

- Weight 110 Kilograms (kg)

- Color Gray

- Length 35 Inch (in)

- Click to View more

X

Rotor Brazing Machine Price And Quantity

- 1 Unit

- 195000.0 INR/Unit

Rotor Brazing Machine Product Specifications

- Induction Brazing

- submersible rotor brazing

- Gray

- 35 Inch (in)

- Rotor Brazing Machine

- 31 Inch (in)

- 110 Kilograms (kg)

- 56 Inch (in)

Rotor Brazing Machine Trade Information

- 10 Unit Per Week

- 1 Week

- No

- All India

Product Description

Submersible Pump Rotor Brazing Machine is a high-performance, precision-engineered induction brazing solution designed specifically for brazing rotors used in submersible pump assemblies. Built to deliver consistent and reliable brazing joints, this machine ensures strong mechanical bonding and superior electrical conductivity critical for long-lasting pump performance.

Key Features:

-

Precision Induction Heating: Uniform and controlled heating ensures flawless brazing with minimal thermal distortion.

-

High Efficiency: Rapid heating cycles reduce process time, increasing productivity and reducing energy costs.

-

User-Friendly Interface: Intuitive controls with programmable settings for consistent and repeatable results.

-

Sturdy Construction: Industrial-grade components built for continuous operation in demanding environments.

-

Automatic or Manual Operation Options: Adaptable to various production scales, from batch to mass production.

-

Specification/Additional Details

Advanced Induction Brazing Technology

Utilizing innovative induction heating, the Rotor Brazing Machine ensures precise and uniform brazing for submersible rotor components. This technology delivers rapid heating, promoting high-quality joints and reducing overall processing time. Its integration is ideal for demanding industrial settings where efficiency and reliability are paramount.

Optimized for Industrial Use

Specially designed for industrial rotor brazing applications, the machine excels as both a heat treatment furnace and a precision brazing system. The robust construction and thoughtfully engineered dimensions allow easy placement and operation in manufacturing environments. Exporters, manufacturers, and suppliers in India benefit from its tailored capabilities.

FAQs of Rotor Brazing Machine:

Q: How does the Rotor Brazing Machine work in industrial heat treatment?

A: The Rotor Brazing Machine employs induction brazing technology to heat submersible rotors evenly, ensuring strong and consistent joints. It acts as a heat treatment furnace, rapidly reaching required temperatures for precise and efficient rotor assembly.Q: What type of rotors can be processed using this machine?

A: This machine is specifically designed for submersible rotors used in industrial applications. Its versatile heat treatment capabilities make it suitable for various rotor sizes and materials, optimizing brazing quality and durability.Q: When should manufacturers consider using induction brazing for rotor assembly?

A: Manufacturers should opt for induction brazing when high-speed, accurate, and repeatable rotor joining is essential. This method is ideal for high-volume production and scenarios requiring strong, consistent joints.Q: Where is the Rotor Brazing Machine commonly used within industrial settings?

A: The machine is typically installed in manufacturing plants, assembly workshops, and heat treatment facilities across India. Its compact design allows for easy integration into existing production lines.Q: What is the process involved in brazing submersible rotors with this equipment?

A: The process involves placing the rotor in the machines furnace, where induction coils generate localized heat, melting brazing alloys and forming a robust bond. The entire operation is controlled for accuracy and consistency.Q: How is this rotor brazing machine beneficial for exporters, manufacturers, and suppliers in India?

A: The machine offers dependable performance, streamlined operation, and reduced lead times, supporting exporters, manufacturers, and suppliers with enhanced productivity and lower maintenance needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email