- Home Page

- Company Profile

-

Our Products

- Induction Melting Machine

- Gold Melting Machine

- Induction Based Gold Melting Machine 500 Gms. In Single Phase

- Induction Based Gold Melting Machine

- Gold Melting Machine 3PH

- Induction Based Gold Melting Machine 20 kg. With Tilting Unit

- Induction Based Gold Melting Machine 10 Kg. With Tilting Unit

- Silver Melting Machine

- Induction Based Melting Machine 10 kg. With Tilting Unit

- Gold Melting Machine 12Kg With Tilting Unit

- Induction Based Gold Melting Machine 3 Kg. In Three Phase

- Induction Melting Machine With Tilting Unit

- Induction Based Gold Melting Machine 30 Kg. With Tilting Unit

- Induction Based Gold Melting Machine 2 Kg. In Three Phase

- Induction Gold Melting Machine

- Induction Based Melting Machine 500 Gms. In Sigle Phase

- Jewelry Melting Furnace

- Gold Melting Furnace

- Induction Melting Furnace

- Induction Based Gold Melting Furnace 2 Kg. In 3PH

- Induction Based Gold Melting Furnace 3 Kg. In 3PH

- Induction Based Gold Melting Furnace 5 Kg. In Three Phase

- Induction Based Gold Melting Furnace 12 Kg. With Tilting Unit

- Gold Melting Furnace

- induction Melting Machine

- Mini Plus Gold Melting Machine 1 Kg. In Single Phase

- Induction Based Gold Melting Furnace 4 Kg in Three Phase

- Induction Based Gold Melting Furnace

- Induction Based Gold Melting Machine In Single Phase

- Induction Based Gold Melting Furnace 500 Gms. In Single Phase

- Induction Based Gold Melting Furnace 8 kg. With Tilting Unit

- Induction Based Gold Melting Furnace 15 kG. With Tilting Unit

- Induction Based Gold Melting Furnace 20 Kg. With Tilting Unit

- Induction Based Gold Melting Furnace 25 Kg. With Tilting Unit

- Induction Based Gold Melting Furnace 30 Kg. With Tilting Unit

- Gold Casting Machine

- Bottom Pouring Vacuum Casting Machine

- Induction Based Gold Casting Machine 2 kg. In Three Phase

- Induction Based Casting Machine

- Induction Based Gold Casting Furnace 3 Kg In Single Phase

- Gold Casting Machine

- 3 in 1 Gold Casting Machine

- Induction Based Gold Casting Machine 1 kg. In Single Phase

- Jewellery Casting Machine

- Gold Bar Making Machine

- 1 Kg Bar Vacuum Casting Making Machine

- Bar Making Machine 100grm 4 Bar At A Time

- Induction Based Gold Casting Machine 3 kg. Three Phase

- Induction Based Jewellery Casting Machine

- jewelry vacuum casting unit

- 1kg Gold Casting Machine

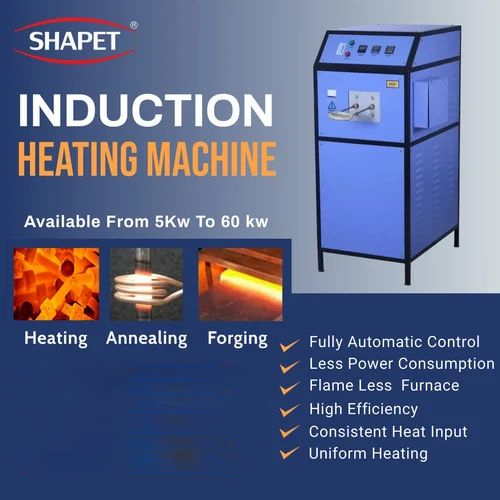

- Heating Machine

- Silver Melting Machine

- Gold And Silver Granulating Machine With Inbuilt Chiller

- Induction melting machine 3PH

- Induction Based Silver Melting Furnace

- Silver Melting Furnace With Tilting

- Induction melting machine

- Induction Based Silver Melting Machine 250 Gms. In Single Phase

- Induction Based Silver Melting Machine 1.5 Kg. In Three Phase

- Induction Based Silver Melting Machine 2 Kg.In Three Phase

- Induction Based Silver Melting Machine 2.5 Kg. In Three Phase

- Induction Based Silver Melting Machine 4 kg. With Tilting Unit

- Induction Based Silver Melting Machine 5 Kg. With Tilting Unit

- Induction Based Silver Melting Machine 7.5 Kg. With Tilting Unit

- Induction Based Silver Melting Machine 10 kG. With Tilting Unit

- Induction Based Silver Melting Machine 15 Kg. With Tilting Unit

- Silver Melting Furnace

- Induction Based Melting Furnace 5 kg. With Titing Unit

- Silver Melting Furnace

- Induction Based Silver Melting Machine 05 KG WITH MELTING POT

- Induction Based Silver Melting Furnace 1 kg. In Three Phase

- Induction Based Silver Melting Furnace 1.5 Kg. In Three Phase

- Induction Based Silver Melting Furnace 2 kg. In Three Phase

- Induction Based Silver Melting Furnace 2.5 Kg. In Three Phase

- Induction Based Silver Melting Furnace 5 kg. With Tilting Unit

- Induction Based Silver Melting Furnace 6 Kg. With Tilting Unit

- Induction Based Silver Melting Furnace 7.5 Kg. With Tilting Unit

- Induction Based Silver Melting Furnace 10 kg. With Tilting Unit

- Induction Based Silver Melting Furnace 15 kg. With Tilting Unit

- Induction Based Silver Melting furnace 12.5 Kg. With Tilting Unit

- Silver Casting Furnace

- Silver Casting Machine

- Copper Melting Furnace

- Induction Based Copper Melting Furnace with Tilting Unit

- Induction Based Copper Melting Furnace

- 3PH Induction Based Copper Melting Furnace

- 10 Kg. Induction Based Silver Melting Furnace

- Induction Copper Melting Furnace

- Copper Melting Furnace

- Copper Melting Furnace with Hydraulic Tilting Unit

- Copper Melting Furnace

- Single Phase Induction Based Copper Melting Furnace

- Induction Based Melting Furnace 10 kg. With Tilting Unit

- Three Phase Copper Melting Furnace

- Induction Copper Melting Furnace

- Copper Melting Machine

- Melting Machine For Gold / Silver

- Copper Melting Machine with Tilting Unit

- Induction Based Copper Melting Machine

- Copper Melting Machine

- Induction Based Copper Melting Machine 1.5 kg. In Three Phase

- Induction Based Copper Melting Machine 2 kg. In Three Phase

- Induction Based Copper Melting Machine 2.5 kg. In Three Phase

- Induction Based Copper Melting Machine 4 Kg. With Tilting Unit

- induction Based Copper Melting Machine 5 kg. With Tilting Unit

- Induction Based Copper Melting Machine 15 Kg. With Tilting Unit

- Gold Melting Machine

- Carbon & Graphite Products

- Imitation Casting

- Induction Brazing Machine

- Gold Casting Furnace

- jewellery casting

- Imitation Casting Machine

- Induction Melting Machine

- Gallery

- Contact Us

SS Utensils Annealing Machine Furnace

310000 INR/Unit

Product Details:

- Voltage 440 Volt (v)

- Material Steel

- Application Industrial

- Product Type SS Utensils Annealing Machine Furnace

- Color Blue

- Click to View more

X

SS Utensils Annealing Machine Furnace Price And Quantity

- 310000 INR/Unit

- 1 Unit

SS Utensils Annealing Machine Furnace Product Specifications

- SS Utensils Annealing Machine Furnace

- Industrial

- 440 Volt (v)

- Steel

- Blue

SS Utensils Annealing Machine Furnace Trade Information

- 10 Unit Per Week

- 1 Week

- All India

Product Description

Induction Annealing Is A Sub- Area Of Induction Heating. The Aim of Induction Annealing Is to Specifically Influence Metals with Regard To Hardness, Toughness And Internal Stresses, In Order To Attain Optimal Material Property. Induction Annealing Enables Precise And Reliable Control of Material Properties. Induction Annealing Is Mainly Used For Soft And Stress-Relief Annealing, Offering Enormous Advantages Over Conventional Method. Induction Annealing Enables Thermal Removal of Impurities During Bright Annealing.The Advantage of Induction Annealing Is Mainly The Targeted and Reproducible Heating of Work Pieces in Order To Always Ensure The Same Result. As Induction Annealing Generates Heat Directly In The Work Pieces By Means of An Alternating Electromagnetic Field, The Process Can Be Controlled Very Precisely And Also Has A Very High Degree of Efficiency Due To Its Effective Use of Energy. This Ensures Homogeneous Heat Destruction And An Even Depth of Penetration In The Work Pieces. With Induction Annealing, Cooling Is Not Carried Out Abruptly With Water Or Coolants As In Induction Hardening. Instead, The Temperature of The Work Piece Is Reduces Slowly.

Specification/Additional Details

Efficient Annealing for SS Utensils

This furnace is tailored for smoothing and strengthening steel and stainless steel utensils. By providing consistent heat treatment, it improves the grain structure, leading to products with enhanced durability and corrosion resistance. Industrial operations benefit from its semi-automatic functionality, enabling streamlined production with reduced manual oversight.

Industrial-Grade Performance

Designed for the demands of high-volume manufacturing, the furnace operates with 440 volts of electric power. Its solid steel build paired with a blue finish signals reliability and modern aesthetics. Whether you are an exporter, manufacturer, or supplier in India, this machine delivers the efficiency required for competitive utensil production.

FAQs of SS Utensils Annealing Machine Furnace:

Q: How does the SS Utensils Annealing Machine Furnace improve utensil quality?

A: The furnace enhances the physical and chemical properties of steel and stainless steel utensils by applying controlled heat for annealing, resulting in better durability, flexibility, and resistance to corrosion.Q: What materials can be processed in this annealing furnace?

A: This machine is engineered to treat both steel and stainless steel utensils, ensuring optimum results for industrial-grade kitchenware production.Q: When should I use the annealing process in utensil manufacturing?

A: Annealing is typically applied after initial shaping or forming utensils to relieve stress, refine grain structure, and boost overall material performance before finishing or further processing.Q: Where can the SS Utensils Annealing Machine Furnace be installed?

A: It is suitable for industrial facilities, manufacturing units, or export-oriented factories across India who require efficient and reliable annealing capability for utensils.Q: What is the operating voltage and power source of the furnace?

A: The furnace operates at 440 volts and is powered electrically, which supports stable performance and easy integration into industrial power systems.Q: What are the benefits of using this semi-automatic furnace model?

A: Using a semi-automatic furnace streamlines production, reduces manual intervention, and increases consistency in annealing results, contributing to improved product quality and operational efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email