- Home Page

- Company Profile

-

Our Products

- Induction Melting Machine

- Gold Melting Machine

- Induction Based Gold Melting Machine 500 Gms. In Single Phase

- Induction Based Gold Melting Machine

- Gold Melting Machine 3PH

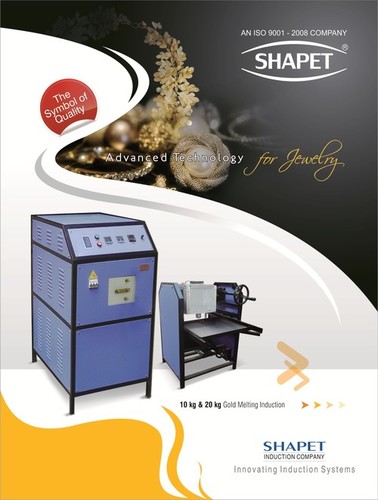

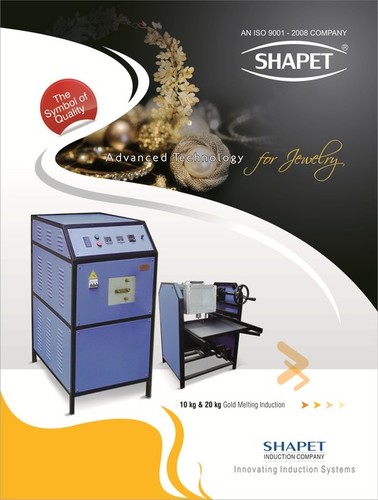

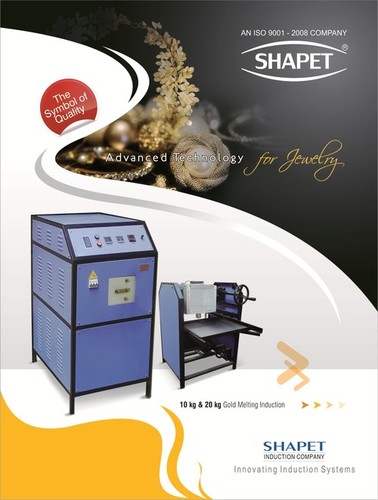

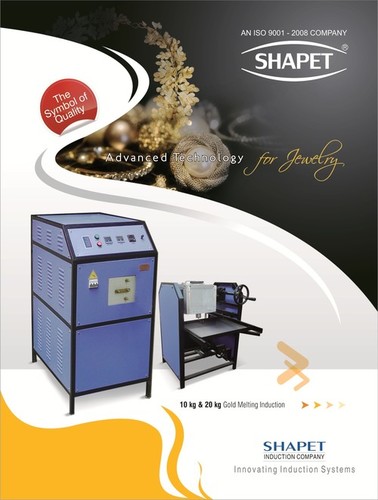

- Induction Based Gold Melting Machine 20 kg. With Tilting Unit

- Induction Based Gold Melting Machine 10 Kg. With Tilting Unit

- Silver Melting Machine

- Induction Based Melting Machine 10 kg. With Tilting Unit

- Gold Melting Machine 12Kg With Tilting Unit

- Induction Based Gold Melting Machine 3 Kg. In Three Phase

- Induction Melting Machine With Tilting Unit

- Induction Based Gold Melting Machine 30 Kg. With Tilting Unit

- Induction Based Gold Melting Machine 2 Kg. In Three Phase

- Induction Gold Melting Machine

- Induction Based Melting Machine 500 Gms. In Sigle Phase

- Jewelry Melting Furnace

- Gold Melting Furnace

- Induction Melting Furnace

- Induction Based Gold Melting Furnace 2 Kg. In 3PH

- Induction Based Gold Melting Furnace 3 Kg. In 3PH

- Induction Based Gold Melting Furnace 5 Kg. In Three Phase

- Induction Based Gold Melting Furnace 12 Kg. With Tilting Unit

- Gold Melting Furnace

- induction Melting Machine

- Mini Plus Gold Melting Machine 1 Kg. In Single Phase

- Induction Based Gold Melting Furnace 4 Kg in Three Phase

- Induction Based Gold Melting Furnace

- Induction Based Gold Melting Machine In Single Phase

- Induction Based Gold Melting Furnace 500 Gms. In Single Phase

- Induction Based Gold Melting Furnace 8 kg. With Tilting Unit

- Induction Based Gold Melting Furnace 15 kG. With Tilting Unit

- Induction Based Gold Melting Furnace 20 Kg. With Tilting Unit

- Induction Based Gold Melting Furnace 25 Kg. With Tilting Unit

- Induction Based Gold Melting Furnace 30 Kg. With Tilting Unit

- Gold Casting Machine

- Bottom Pouring Vacuum Casting Machine

- Induction Based Gold Casting Machine 2 kg. In Three Phase

- Induction Based Casting Machine

- Induction Based Gold Casting Furnace 3 Kg In Single Phase

- Gold Casting Machine

- 3 in 1 Gold Casting Machine

- Induction Based Gold Casting Machine 1 kg. In Single Phase

- Jewellery Casting Machine

- Gold Bar Making Machine

- 1 Kg Bar Vacuum Casting Making Machine

- Bar Making Machine 100grm 4 Bar At A Time

- Induction Based Gold Casting Machine 3 kg. Three Phase

- Induction Based Jewellery Casting Machine

- jewelry vacuum casting unit

- 1kg Gold Casting Machine

- Heating Machine

- Silver Melting Machine

- Gold And Silver Granulating Machine With Inbuilt Chiller

- Induction melting machine 3PH

- Induction Based Silver Melting Furnace

- Silver Melting Furnace With Tilting

- Induction melting machine

- Induction Based Silver Melting Machine 250 Gms. In Single Phase

- Induction Based Silver Melting Machine 1.5 Kg. In Three Phase

- Induction Based Silver Melting Machine 2 Kg.In Three Phase

- Induction Based Silver Melting Machine 2.5 Kg. In Three Phase

- Induction Based Silver Melting Machine 4 kg. With Tilting Unit

- Induction Based Silver Melting Machine 5 Kg. With Tilting Unit

- Induction Based Silver Melting Machine 7.5 Kg. With Tilting Unit

- Induction Based Silver Melting Machine 10 kG. With Tilting Unit

- Induction Based Silver Melting Machine 15 Kg. With Tilting Unit

- Silver Melting Furnace

- Induction Based Melting Furnace 5 kg. With Titing Unit

- Silver Melting Furnace

- Induction Based Silver Melting Machine 05 KG WITH MELTING POT

- Induction Based Silver Melting Furnace 1 kg. In Three Phase

- Induction Based Silver Melting Furnace 1.5 Kg. In Three Phase

- Induction Based Silver Melting Furnace 2 kg. In Three Phase

- Induction Based Silver Melting Furnace 2.5 Kg. In Three Phase

- Induction Based Silver Melting Furnace 5 kg. With Tilting Unit

- Induction Based Silver Melting Furnace 6 Kg. With Tilting Unit

- Induction Based Silver Melting Furnace 7.5 Kg. With Tilting Unit

- Induction Based Silver Melting Furnace 10 kg. With Tilting Unit

- Induction Based Silver Melting Furnace 15 kg. With Tilting Unit

- Induction Based Silver Melting furnace 12.5 Kg. With Tilting Unit

- Silver Casting Furnace

- Silver Casting Machine

- Copper Melting Furnace

- Induction Based Copper Melting Furnace with Tilting Unit

- Induction Based Copper Melting Furnace

- 3PH Induction Based Copper Melting Furnace

- 10 Kg. Induction Based Silver Melting Furnace

- Induction Copper Melting Furnace

- Copper Melting Furnace

- Copper Melting Furnace with Hydraulic Tilting Unit

- Copper Melting Furnace

- Single Phase Induction Based Copper Melting Furnace

- Induction Based Melting Furnace 10 kg. With Tilting Unit

- Three Phase Copper Melting Furnace

- Induction Copper Melting Furnace

- Copper Melting Machine

- Melting Machine For Gold / Silver

- Copper Melting Machine with Tilting Unit

- Induction Based Copper Melting Machine

- Copper Melting Machine

- Induction Based Copper Melting Machine 1.5 kg. In Three Phase

- Induction Based Copper Melting Machine 2 kg. In Three Phase

- Induction Based Copper Melting Machine 2.5 kg. In Three Phase

- Induction Based Copper Melting Machine 4 Kg. With Tilting Unit

- induction Based Copper Melting Machine 5 kg. With Tilting Unit

- Induction Based Copper Melting Machine 15 Kg. With Tilting Unit

- Gold Melting Machine

- Carbon & Graphite Products

- Imitation Casting

- Induction Brazing Machine

- Gold Casting Furnace

- jewellery casting

- Induction Melting Machine

- Gallery

- Contact Us

Induction Based Silver Melting Furnace 10 kg. With Tilting Unit

420000.00 INR/Unit

Product Details:

- Condition New

- Usage Melting Furnace

- Power 16 Watt (w)

- Voltage 440 Volt (v)

- Product Type Silver Melting Furnace

- Size 80 x 60 x 113 (cms)

- Color Gray

- Click to View more

X

Induction Based Silver Melting Furnace 10 kg. With Tilting Unit Price And Quantity

- 1 Unit

- 420000.00 INR/Unit

Induction Based Silver Melting Furnace 10 kg. With Tilting Unit Product Specifications

- Gray

- New

- Silver Melting Furnace

- Industrial

- 10 Kg/hr

- Electricity

- 1 Year

- 80 x 60 x 113 (cms)

- Melting Furnace

- 16 Watt (w)

- 79 Kilograms (kg)

- 440 Volt (v)

Induction Based Silver Melting Furnace 10 kg. With Tilting Unit Trade Information

- Cheque

- 10 Unit Per Week

- 1 Week

- No

- Asia

- All India

Product Description

Induction Based Silver Melting 10 Kg With Tilting UnitUseful for:

High volume jewellery manufacturers, Alloy manufacturers, Chain manufacturers, Metal processing refineries, Useful for coins and bar manufacturers.

Product Features:

- Perfect Homogeneous mixing due to auto stirring effect for increased productivity and perfect alloying.

- Economical, Efficient and Simple in Operation.

- Energy saving flameless device and also 80% income tax depreciable.

- Does not affect room temperature.

- Heat and power loss reduced.

- Works on 3 Phase connection.

- Provides controlled pouring of metal due to manual tilting unit.

- Metal can be added easily during the melting process for continuous melting operation.

Technical Specifications:

- Technology: IGBT Based.

- Power Supply & Voltage: 3 Phase 440 Volts A/C

- Absorbed Power: 16 KW/H.

- Capacity of Crucible: 10 Kgs. Silver.

- Maximum Temperature & Type: 12000 Degrees, "K" Type.

- Melting Time: 12 to 15 Minutes.

- Cooling Water Temperature: 350 Degrees Max.

- Machine Weight: Approx 79 Kgs.

- Chiller Weight: Approx 130.5 Kgs.

- Tilting Weight: Approx 60 kgs.

- Machine Size (LxWxH): Approx 80 x 60 x 113 (cms).

- Chiller Size (LxWxH): Approx 84 x 59 x 105 (cms).

- Tilting Size (LxWxH): Approx 84 x 62 x 92 (cms).

Advanced Melting Technology

Induction heating in this furnace delivers rapid and consistent melting. Designed for gold and silver, it achieves accurate temperature control while its robust build contributes to reliable, maintenance-friendly operation.

User-Friendly Tilting Unit

The integrated tilting unit ensures effortless metal pouring while reducing labor risks. This feature streamlines workflow, allowing for cleaner and safer transfer of molten metals in industrial settings.

Energy Efficient Performance

Operating on standard 440 Volt electricity, this furnace optimizes power consumption at just 16 Watts, providing high performance with minimal energy usage. Its modern design maximizes output and reduces operational costs.

FAQs of Induction Based Silver Melting Furnace 10 kg. With Tilting Unit:

Q: How does the tilting unit on the 10 kg Induction Based Silver Melting Furnace enhance safety and efficiency during metal pouring?

A: The tilting unit allows operators to pour molten silver or gold smoothly and safely, minimizing the risk of spills or accidents. It improves efficiency by providing better control during transfer and reduces manual handling.Q: What is the typical process for melting silver or gold using this induction furnace?

A: Operators place the raw metal into the crucible and set the required temperature. The induction heating system rapidly melts the contents to a uniform, pourable state, and the tilting unit is then used to transfer the molten metal to molds or containers.Q: When should this furnace be used in an industrial metalworking operation?

A: This furnace is ideal for industrial settings when precise melting and casting of gold and silver are required, such as in jewelry manufacturing, metal refining, or precious metal recycling.Q: Where can the Induction Based Silver Melting Furnace be installed?

A: The furnace can be installed in workshops, industrial plants, or manufacturing units where metal melting and casting are performed. Its size and electrical requirements make it suitable for standard industrial environments.Q: What are the key benefits of using an induction-based melting furnace over traditional fuel-based alternatives?

A: Induction furnaces offer faster heating, precise temperature control, improved energy efficiency, and cleaner operation as they use electricity instead of fossil fuels. This reduces emissions and lowers overall operational costs.Q: How does the furnace ensure consistent melting quality?

A: The induction heating mechanism ensures even heat distribution throughout the crucible, preventing hot spots and resulting in a homogenous melt, which is essential for high-quality casting outputs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email