- Home Page

- Company Profile

-

Our Products

- Induction Melting Machine

- Induction Based Melting Machine 10 kg. With Tilting Unit

- Induction Based Gold Melting Machine 20 kg. With Tilting Unit

- Induction Based Gold Melting Machine 10 Kg. With Tilting Unit

- Silver Melting Machine

- Gold Melting Machine

- Gold Melting Machine 12Kg With Tilting Unit

- Induction Based Gold Melting Machine 3 Kg. In Three Phase

- Induction Based Gold Melting Machine 500 Gms. In Single Phase

- Induction Melting Machine With Tilting Unit

- Induction Based Gold Melting Machine

- Induction Based Gold Melting Machine 30 Kg. With Tilting Unit

- Induction Based Gold Melting Machine 2 Kg. In Three Phase

- Gold Melting Machine 3PH

- Induction Gold Melting Machine

- Induction Based Melting Machine 500 Gms. In Sigle Phase

- Jewelry Melting Furnace

- Gold Melting Furnace

- Induction Based Gold Melting Furnace 4 Kg in Three Phase

- Induction Based Gold Melting Furnace 2 Kg. In 3PH

- Induction Based Gold Melting Furnace 12 Kg. With Tilting Unit

- Induction Based Gold Melting Furnace 3 Kg. In 3PH

- Induction Based Gold Melting Furnace 5 Kg. In Three Phase

- Mini Plus Gold Melting Machine 1 Kg. In Single Phase

- Induction Based Gold Melting Furnace

- Gold Melting Furnace

- Induction Melting Furnace

- induction Melting Machine

- Induction Based Gold Melting Machine In Single Phase

- Induction Based Gold Melting Furnace 500 Gms. In Single Phase

- Induction Based Gold Melting Furnace 8 kg. With Tilting Unit

- Induction Based Gold Melting Furnace 15 kG. With Tilting Unit

- Induction Based Gold Melting Furnace 20 Kg. With Tilting Unit

- Induction Based Gold Melting Furnace 25 Kg. With Tilting Unit

- Induction Based Gold Melting Furnace 30 Kg. With Tilting Unit

- Gold Casting Machine

- Bottom Pouring Vacuum Casting Machine

- Induction Based Gold Casting Machine 2 kg. In Three Phase

- Induction Based Casting Machine

- Induction Based Gold Casting Furnace 3 Kg In Single Phase

- Gold Casting Machine

- 3 in 1 Gold Casting Machine

- Induction Based Gold Casting Machine 1 kg. In Single Phase

- Jewellery Casting Machine

- Gold Bar Making Machine

- 1 Kg Bar Vacuum Casting Making Machine

- Bar Making Machine 100grm 4 Bar At A Time

- Induction Based Gold Casting Machine 3 kg. Three Phase

- Induction Based Jewellery Casting Machine

- jewelry vacuum casting unit

- 1kg Gold Casting Machine

- Heating Machine

- Silver Melting Machine

- Gold And Silver Granulating Machine With Inbuilt Chiller

- Silver Melting Furnace With Tilting

- Induction melting machine 3PH

- Induction Based Silver Melting Furnace

- Induction melting machine

- Induction Based Silver Melting Machine 250 Gms. In Single Phase

- Induction Based Silver Melting Machine 1.5 Kg. In Three Phase

- Induction Based Silver Melting Machine 2 Kg.In Three Phase

- Induction Based Silver Melting Machine 2.5 Kg. In Three Phase

- Induction Based Silver Melting Machine 4 kg. With Tilting Unit

- Induction Based Silver Melting Machine 5 Kg. With Tilting Unit

- Induction Based Silver Melting Machine 7.5 Kg. With Tilting Unit

- Induction Based Silver Melting Machine 10 kG. With Tilting Unit

- Induction Based Silver Melting Machine 15 Kg. With Tilting Unit

- Silver Melting Furnace

- Induction Based Melting Furnace 5 kg. With Titing Unit

- Induction Based Silver Melting Machine 05 KG WITH MELTING POT

- Silver Melting Furnace

- Induction Based Silver Melting Furnace 1 kg. In Three Phase

- Induction Based Silver Melting Furnace 1.5 Kg. In Three Phase

- Induction Based Silver Melting Furnace 2 kg. In Three Phase

- Induction Based Silver Melting Furnace 2.5 Kg. In Three Phase

- Induction Based Silver Melting Furnace 5 kg. With Tilting Unit

- Induction Based Silver Melting Furnace 6 Kg. With Tilting Unit

- Induction Based Silver Melting Furnace 7.5 Kg. With Tilting Unit

- Induction Based Silver Melting Furnace 10 kg. With Tilting Unit

- Induction Based Silver Melting Furnace 15 kg. With Tilting Unit

- Induction Based Silver Melting furnace 12.5 Kg. With Tilting Unit

- Silver Casting Furnace

- Silver Casting Machine

- Copper Melting Furnace

- Induction Based Copper Melting Furnace with Tilting Unit

- Induction Based Copper Melting Furnace

- 10 Kg. Induction Based Silver Melting Furnace

- Induction Copper Melting Furnace

- 3PH Induction Based Copper Melting Furnace

- Copper Melting Furnace with Hydraulic Tilting Unit

- Copper Melting Furnace

- Single Phase Induction Based Copper Melting Furnace

- Induction Based Melting Furnace 10 kg. With Tilting Unit

- Copper Melting Furnace

- Three Phase Copper Melting Furnace

- Induction Copper Melting Furnace

- Copper Melting Machine

- Copper Melting Machine with Tilting Unit

- Induction Based Copper Melting Machine

- Melting Machine For Gold / Silver

- Copper Melting Machine

- Induction Based Copper Melting Machine 1.5 kg. In Three Phase

- Induction Based Copper Melting Machine 2 kg. In Three Phase

- Induction Based Copper Melting Machine 2.5 kg. In Three Phase

- Induction Based Copper Melting Machine 4 Kg. With Tilting Unit

- induction Based Copper Melting Machine 5 kg. With Tilting Unit

- Induction Based Copper Melting Machine 15 Kg. With Tilting Unit

- Gold Melting Machine

- Carbon & Graphite Products

- Imitation Casting

- Induction Brazing Machine

- Gold Casting Furnace

- jewellery casting

- Imitation Casting Machine

- Induction Melting Machine

- Gallery

- Contact Us

Copper Melting Furnace

484000.0 INR/Piece

Product Details:

- Feature Perfect Homogeneous mixing due to auto stirring effect for increased productivity and perfect alloying

- Condition New

- Type Induction Based

- Usage Melting Furnace

- Height 1130 Millimeter (mm)

- Voltage 440 Volt (v)

- Product Type Induction Based gold Melting Machine

- Click to View more

X

Copper Melting Furnace Price And Quantity

- 484000.0 INR/Piece

- 1 Piece

Copper Melting Furnace Product Specifications

- Melting Furnace

- 840 Millimeter (mm)

- 70 Kilograms (kg)

- Perfect Homogeneous mixing due to auto stirring effect for increased productivity and perfect alloying

- 440 Volt (v)

- 1130 Millimeter (mm)

- Gold Melting

- Induction Based gold Melting Machine

- 590 Millimeter (mm)

- Induction Based

- New

- 12 Kg/hr

Copper Melting Furnace Trade Information

- Kandla Port

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 10 Piece Per Week

- 1 Week

- Contact us for information regarding our sample policy

- Our standard procedure for ensuring the safe transportation of our machines is to pack them in form sheets and then place them in wooden boxes. This method has proven to be effective in preventing any damage during transit.

- All India

Product Description

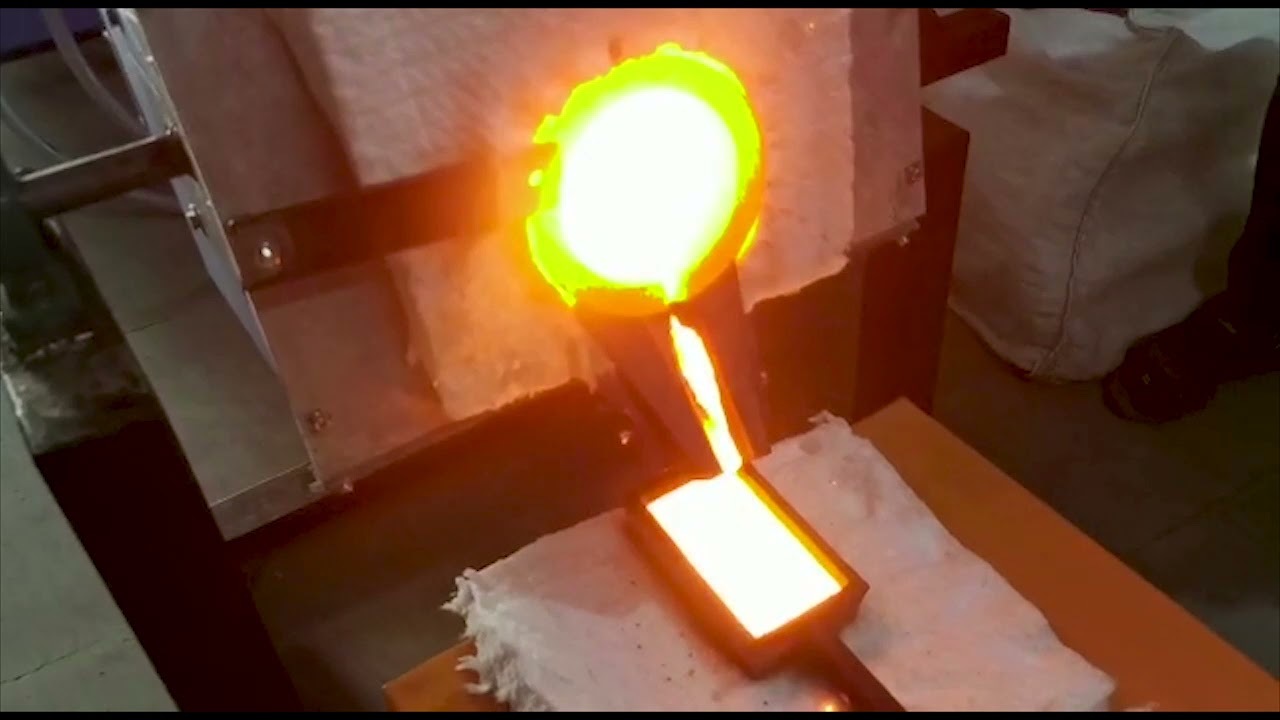

Induction Based Copper Melting 25Kg. With Tilting UnitUseful for:

High volume jewellery manufacturers, Alloy manufacturers, Chain manufacturers, Metal processing refineries, Useful for coins and bar manufacturers.

Product Features:

- Perfect Homogeneous mixing due to auto stirring effect for increased productivity and perfect alloying.

- Economical, Efficient and Simple in Operation.

- Energy saving flameless device and also 80% income tax depreciable.

- Does not affect room temperature.

- Heat and power loss reduced.

- Works on 3 Phase connection.

- Provides controlled pouring of metal due to manual tilting unit.

- Metal can be added easily during the melting process for continuous melting operation.

- Technology: IGBT Based.

- Power Supply & Voltage: 3 Phase 440 Volts A/C

- Absorbed Power: 20 KW/H.

- Capacity of Crucible: 25 Kgs. Gold.

- Maximum Temperature & Type: 12000 Degrees, "K" Type.

- Melting Time: 15 to 20 Minutes.

- Cooling Water Temperature: 350 Degrees Max.

- Machine Weight: Approx 79 Kgs.

- Chiller Weight: Approx 130.5 Kgs.

- Tilting Weight: Approx 60 kgs.

- Machine Size (LxWxH): Approx 80 x 60 x 113 (cms).

- Chiller Size (LxWxH): Approx 84 x 59 x 105 (cms).

- Tilting Size (LxWxH): Approx 84 x 62 x 92 (cms).

Automatic Operation with Advanced Alloying

The furnace features automatic controls combined with an auto-stirring mechanism, guaranteeing perfect mixing and homogeneous alloying. This advantage facilitates increased productivity and consistently high-quality melts essential for precise gold and silver applications.

Robust Design and Efficient Cooling

Built from durable, high-grade materials, the furnace maintains structural integrity even under intense heat, thanks to its water cooling mode. The three-core wire and 3-phase 440V input ensure reliable and safe operation for demanding continuous use.

Application Versatility and User Benefits

Primarily used for gold and silver melting, the units intuitive automatic functions streamline the process. Its design suits manufacturers and exporters requiring reliability, consistent outputs, and improved productivity. The one-year warranty adds confidence for long-term use.

FAQs of Copper Melting Furnace:

Q: How does the automatic function of this furnace enhance gold and silver melting operations?

A: The automatic feature, paired with the auto-stirring mechanism, ensures consistent mixing and temperature control, leading to higher productivity and uniformly alloyed melts during gold and silver processing.Q: What are the main benefits of the water cooling system in this copper melting furnace?

A: The water cooling system maintains optimal operational temperatures, prevents overheating, and extends equipment lifespan, supporting uninterrupted, high-quality melting processes.Q: When is this furnace best utilized within a manufacturing process?

A: This furnace is ideal for use during the gold and silver melting stages, particularly in environments where precise alloy composition and homogeneous mixing are required, such as jewelry manufacturing or metal refining.Q: Where can this induction-based furnace be installed for optimal performance?

A: It is designed for industrial settings like manufacturing plants or metal processing facilities with access to 3-phase 440V power supply and water connections, ensuring safe and efficient operation.Q: What steps are involved in operating this melting furnace?

A: To operate, connect the furnace to a 3-phase 440V AC supply and water cooling line. Load the gold or silver, initiate the automatic cycle, and the furnace will deliver consistent results thanks to its auto-stirring and precise temperature control.Q: How does the design of this furnace contribute to improved alloy quality?

A: The auto-stirring effect facilitates thorough mixing of metals, leading to perfect homogeneous alloys, which results in higher product quality and reduced variability in end outputs.Q: What warranty support is provided with this copper melting furnace?

A: This furnace comes with a comprehensive 1-year warranty, ensuring support for manufacturing defects and providing users with peace of mind regarding performance and reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email