- Home Page

- Company Profile

-

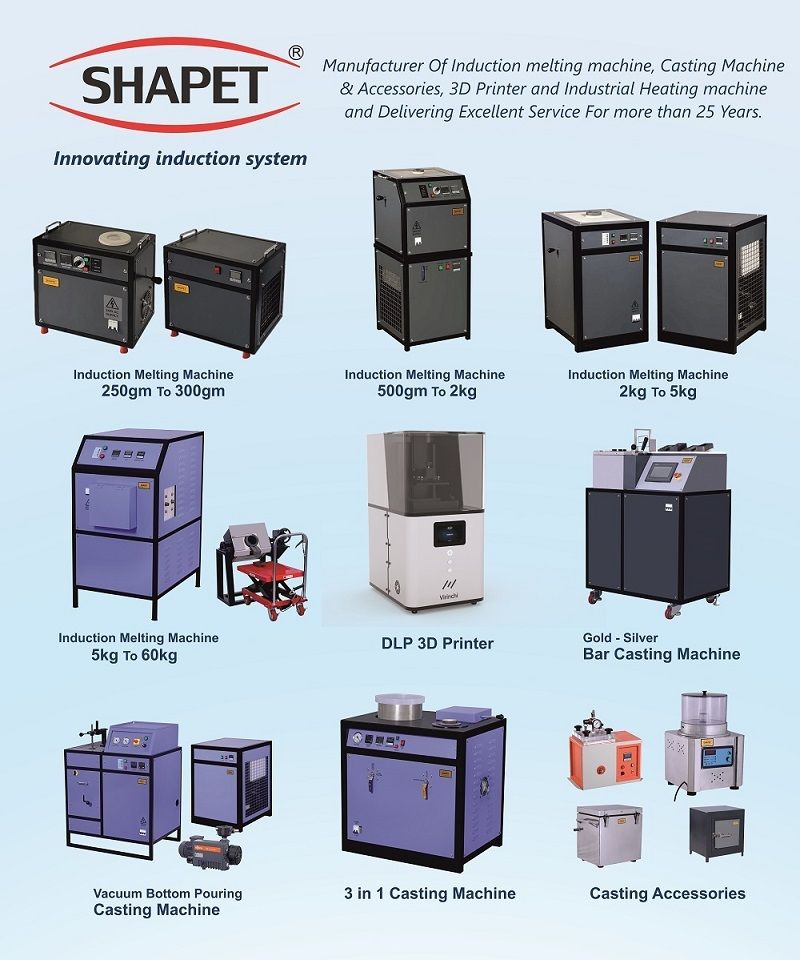

Our Products

- Induction Melting Machine

- Induction Based Melting Machine 10 kg. With Tilting Unit

- Induction Based Gold Melting Machine 20 kg. With Tilting Unit

- Induction Based Gold Melting Machine 10 Kg. With Tilting Unit

- Silver Melting Machine

- Gold Melting Machine

- Gold Melting Machine 12Kg With Tilting Unit

- Induction Based Gold Melting Machine 3 Kg. In Three Phase

- Induction Based Gold Melting Machine 500 Gms. In Single Phase

- Induction Melting Machine With Tilting Unit

- Induction Based Gold Melting Machine

- Induction Based Gold Melting Machine 30 Kg. With Tilting Unit

- Induction Based Gold Melting Machine 2 Kg. In Three Phase

- Gold Melting Machine 3PH

- Induction Gold Melting Machine

- Induction Based Melting Machine 500 Gms. In Sigle Phase

- Jewelry Melting Furnace

- Gold Melting Furnace

- Induction Based Gold Melting Furnace 4 Kg in Three Phase

- Induction Based Gold Melting Furnace 2 Kg. In 3PH

- Induction Based Gold Melting Furnace 12 Kg. With Tilting Unit

- Induction Based Gold Melting Furnace 3 Kg. In 3PH

- Induction Based Gold Melting Furnace 5 Kg. In Three Phase

- Mini Plus Gold Melting Machine 1 Kg. In Single Phase

- Induction Based Gold Melting Furnace

- Gold Melting Furnace

- Induction Melting Furnace

- induction Melting Machine

- Induction Based Gold Melting Machine In Single Phase

- Induction Based Gold Melting Furnace 500 Gms. In Single Phase

- Induction Based Gold Melting Furnace 8 kg. With Tilting Unit

- Induction Based Gold Melting Furnace 15 kG. With Tilting Unit

- Induction Based Gold Melting Furnace 20 Kg. With Tilting Unit

- Induction Based Gold Melting Furnace 25 Kg. With Tilting Unit

- Induction Based Gold Melting Furnace 30 Kg. With Tilting Unit

- Gold Casting Machine

- Bottom Pouring Vacuum Casting Machine

- Induction Based Gold Casting Machine 2 kg. In Three Phase

- Induction Based Casting Machine

- Induction Based Gold Casting Furnace 3 Kg In Single Phase

- Gold Casting Machine

- 3 in 1 Gold Casting Machine

- Induction Based Gold Casting Machine 1 kg. In Single Phase

- Jewellery Casting Machine

- Gold Bar Making Machine

- 1 Kg Bar Vacuum Casting Making Machine

- Bar Making Machine 100grm 4 Bar At A Time

- Induction Based Gold Casting Machine 3 kg. Three Phase

- Induction Based Jewellery Casting Machine

- jewelry vacuum casting unit

- 1kg Gold Casting Machine

- Heating Machine

- Silver Melting Machine

- Gold And Silver Granulating Machine With Inbuilt Chiller

- Silver Melting Furnace With Tilting

- Induction melting machine 3PH

- Induction Based Silver Melting Furnace

- Induction melting machine

- Induction Based Silver Melting Machine 250 Gms. In Single Phase

- Induction Based Silver Melting Machine 1.5 Kg. In Three Phase

- Induction Based Silver Melting Machine 2 Kg.In Three Phase

- Induction Based Silver Melting Machine 2.5 Kg. In Three Phase

- Induction Based Silver Melting Machine 4 kg. With Tilting Unit

- Induction Based Silver Melting Machine 5 Kg. With Tilting Unit

- Induction Based Silver Melting Machine 7.5 Kg. With Tilting Unit

- Induction Based Silver Melting Machine 10 kG. With Tilting Unit

- Induction Based Silver Melting Machine 15 Kg. With Tilting Unit

- Silver Melting Furnace

- Induction Based Melting Furnace 5 kg. With Titing Unit

- Induction Based Silver Melting Machine 05 KG WITH MELTING POT

- Silver Melting Furnace

- Induction Based Silver Melting Furnace 1 kg. In Three Phase

- Induction Based Silver Melting Furnace 1.5 Kg. In Three Phase

- Induction Based Silver Melting Furnace 2 kg. In Three Phase

- Induction Based Silver Melting Furnace 2.5 Kg. In Three Phase

- Induction Based Silver Melting Furnace 5 kg. With Tilting Unit

- Induction Based Silver Melting Furnace 6 Kg. With Tilting Unit

- Induction Based Silver Melting Furnace 7.5 Kg. With Tilting Unit

- Induction Based Silver Melting Furnace 10 kg. With Tilting Unit

- Induction Based Silver Melting Furnace 15 kg. With Tilting Unit

- Induction Based Silver Melting furnace 12.5 Kg. With Tilting Unit

- Silver Casting Furnace

- Silver Casting Machine

- Copper Melting Furnace

- Induction Based Copper Melting Furnace with Tilting Unit

- Induction Based Copper Melting Furnace

- 10 Kg. Induction Based Silver Melting Furnace

- Induction Copper Melting Furnace

- 3PH Induction Based Copper Melting Furnace

- Copper Melting Furnace with Hydraulic Tilting Unit

- Copper Melting Furnace

- Single Phase Induction Based Copper Melting Furnace

- Induction Based Melting Furnace 10 kg. With Tilting Unit

- Copper Melting Furnace

- Three Phase Copper Melting Furnace

- Induction Copper Melting Furnace

- Copper Melting Machine

- Copper Melting Machine with Tilting Unit

- Induction Based Copper Melting Machine

- Melting Machine For Gold / Silver

- Copper Melting Machine

- Induction Based Copper Melting Machine 1.5 kg. In Three Phase

- Induction Based Copper Melting Machine 2 kg. In Three Phase

- Induction Based Copper Melting Machine 2.5 kg. In Three Phase

- Induction Based Copper Melting Machine 4 Kg. With Tilting Unit

- induction Based Copper Melting Machine 5 kg. With Tilting Unit

- Induction Based Copper Melting Machine 15 Kg. With Tilting Unit

- Gold Melting Machine

- Carbon & Graphite Products

- Imitation Casting

- Induction Brazing Machine

- Gold Casting Furnace

- jewellery casting

- Imitation Casting Machine

- Induction Melting Machine

- Gallery

- Contact Us

1 kg Three Phase Induction Based Silver Casting Furnace

750000.00 INR/Unit

Product Details:

- Feature Perfect Homogeneous mixing due to auto stirring effect for increased productivity and perfect alloying

- Condition New

- Type Induction Casting

- Usage Melting Furnace

- Product Type Induction Based Casting

- Color Gray

- Application Gold/ Silver Casting

- Click to View more

X

1 kg Three Phase Induction Based Silver Casting Furnace Price And Quantity

- 750000.00 INR/Unit

- 1 Unit

1 kg Three Phase Induction Based Silver Casting Furnace Product Specifications

- New

- Gray

- Induction Casting

- Perfect Homogeneous mixing due to auto stirring effect for increased productivity and perfect alloying

- Gold/ Silver Casting

- Melting Furnace

- Induction Based Casting

- Electricity

1 kg Three Phase Induction Based Silver Casting Furnace Trade Information

- Kandla Port

- Cash on Delivery (COD), Cash in Advance (CID), Cheque

- 10 Unit Per Week

- 1 Week

- Contact us for information regarding our sample policy

- All India

Product Description

Induction Based Silver Casting Furnace 1 Kg. In 3 PhaseUseful for:

Useful For Medium Size Jewellery , Making Pre-studded Jewellery With Stone Setting , Medium scale Quantity Jewellery Manufacturers .

Product Features:

- Accurate Casting Temperature Controlling.

- Advantage of Vacuum Casting hence Optimal Results.

- All Safety Precautions Provided.

- Consistent Quality Of Casting.

- Creative And Innovative Technology.

- Instant Heating With finger tip Controls.

- Less oxidation Casting Due to Bottom pouring Technology.

- Reduced Casting Expenses.

- Useful for both Casting & Melting.

- Safe, Fast , Economical, Efficient and Simple in Operation.

- Energy saving flameless device and also 80% income tax depreciable.

- Heat and power loss reduced.

Technical Specifications:

- Technology: IGBT Based.

- Power Supply & Voltage: Three Phase 415 Volts A/C

- Absorbed Power: 6 KW/H.

- Capacity of Crucible: 1 Kg Silver.

- Maximum Temperature & Type: 12000 Degrees, "K" Type.

- Melting Time: 8 to 10 Minutes.

- Cooling Water Temperature: 200 to 350 Degree.

- Machine & Chiller Weight: Approx 145 Kgs.

- Pump Weight: Approx 51 kgs.

- Machine Size (LxWxH): Approx 82 x 61 x 103 (cms).

- Chiller Size (LxWxH): Approx 56 x 51 x 81 (cms).

- pump Size (LxWxH): Approx 63 x 25 x 36 (cms).

Advanced Auto-Stirring Technology

This furnace incorporates an auto-stirring effect, which guarantees consistent alloying and perfectly blended melts. The automated stirring enhances productivity by reducing manual intervention and ensuring an even distribution of elements, ultimately boosting output quality for gold and silver casting professionals.

Efficient Induction Heating

Induction-based heating enables rapid and energy-efficient melting compared to conventional methods. Operating on three-phase electricity, it offers precise temperature control, minimizes contamination, and reduces oxidation, making it an ideal choice for both small-scale and export-oriented manufacturers.

FAQs of 1 kg Three Phase Induction Based Silver Casting Furnace:

Q: How does the auto-stirring effect improve alloy quality in this induction furnace?

A: The auto-stirring effect ensures perfect homogeneous mixing of metals during the melting process, which results in superior alloying quality. This leads to increased productivity and consistently high-quality gold or silver castings.Q: What is the recommended application area for this furnace?

A: This furnace is primarily designed for gold and silver casting, making it suitable for jewelry manufacturers, exporters, and suppliers who require precise and clean melting processes.Q: When should the furnace be used for casting?

A: The furnace is ideal for use whenever high-quality casting or melting of precious metals like gold or silver is needed, especially in production environments requiring consistent results and productivity.Q: Where is this silver casting furnace typically installed?

A: The furnace is commonly installed in jewelry workshops, manufacturing units, and foundries across India, which specialize in gold or silver casting or alloying.Q: What is the process for operating the induction casting furnace?

A: Simply load the metal into the melting chamber, ensure all safety protocols are followed, and initiate the induction heating process. The auto-stirring mechanism activates automatically, optimizing melt quality and homogeneous alloying.Q: How does the use of electricity benefit casting operations compared to traditional fuel methods?

A: Using electricity for induction heating delivers more precise temperature control, quicker melts, and cleaner results. It eliminates the need for gas or other fuels, making the process eco-friendly and cost-effective.Q: What advantages does the gray induction furnace provide to exporters or suppliers in India?

A: Exporters and suppliers benefit from consistent output, increased productivity, and top-tier alloy quality that meets international standards, positioning their products competitively in the global marketplace.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email